Having in the previous edition the ELK-sheet already very inefficient, traditional charring, and a cooking stove, which allows a secondary air injection is an incomplete combustion (Anila Stove), should have presented today a further Technique to be explained: The pyrolysis

Pyrolysis is understood in principle, the decomposition of organic materials by heat. If you pyrolyzed biomass, wood and plant parts produced mainly charcoal and a number of gaseous substances, with less heat next to the coal and liquid and tar-like materials (wood vinegar, wood tar).

interests us here, however, primarily the production of wood or biochar, so we describe the pyrolysis at higher temperatures.

purpose, the dried biomass (wood, plant parts as well as manure, such as dried chicken manure) in a reactor of air to about 800 ° C heated. By these temperatures, the long-chain carbon compounds of the organic material are broken. This results in pyrolysis and additional heat energy is released, which can be used. The heat can be derived and the very high-energy pyrolysis gases can be burned thanks to modern technology and very low emissions in addition to the heat used to generate electricity. For this, the pyrolysis gases can be cleaned and then an internal combustion engine can be fed, which drives a generator to produce electricity. The waste heat of the engine can be used for heating purposes.

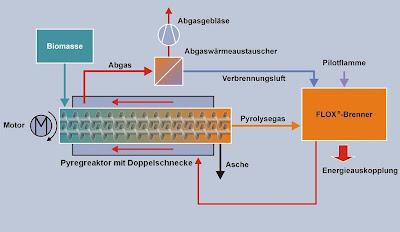

methane, which acts as a greenhouse gas 23 times stronger than carbon dioxide, and nitrous oxide (See previous article in ELK) do not arise in this type of manufacture. After completion of the pyrolysis have been obtained in addition to the electricity generated up to 40% of the initial biomass of Biochar (Bioholzkohle). A first pilot project of this Technique is the PYREG reactor in Ingelheim, Germany (see Figure) which, however, dispense with a power extraction.

building "Pyreg reactor

Pyreg The method is suitable to use any form of biomass for energy. Depending on the structure of the particular reactor and the temperature control either the total biomass is converted to gaseous substances or it is carbonized only part and there is a backlog of pyrolysis (see diagram):

Meanwhile, a small number of companies this subject was adopted and tested in different design units, the implementation of the biomass. Da Terra preta is fairly new to the discussion is limited, the majority of procedures in the production of pyrolysis gas. We assume, however, that this will change in the near future and maybe we can contribute a little to ask for by the companies and Sun to signal that an interest for the production of biochar is the Terra preta.

What are the topic so interesting is the fact that so far there is little reliable information as to what effect the terra preta soils in the home unfolds. So there must be researched much. Since we are now part of the University of Applied Sciences Osnabrück, Faculty of Agricultural Sciences has been contacted, perhaps, for us the possibility of a small modest contribution to make to this research. First opportunities for cooperation, we have already explored. Maybe we can take account first of the Regional Garden Show Present results.

In the next article we will deal with the subject "Hydrothermal Carbonization" closer.

Interested parties can still submit a plan of the furnace "Anila Stove" from the previous edition by email request from us. The previous articles and other information can be found on our web-blog: www.terra-preta-nova.blogspot.com

to questions and suggestions, we like to answer under our

E-mail address: terrapreta@web.de

0 comments:

Post a Comment